Soxmatic

Automatic steam boarding and packaging line for socks.

Soxmatic

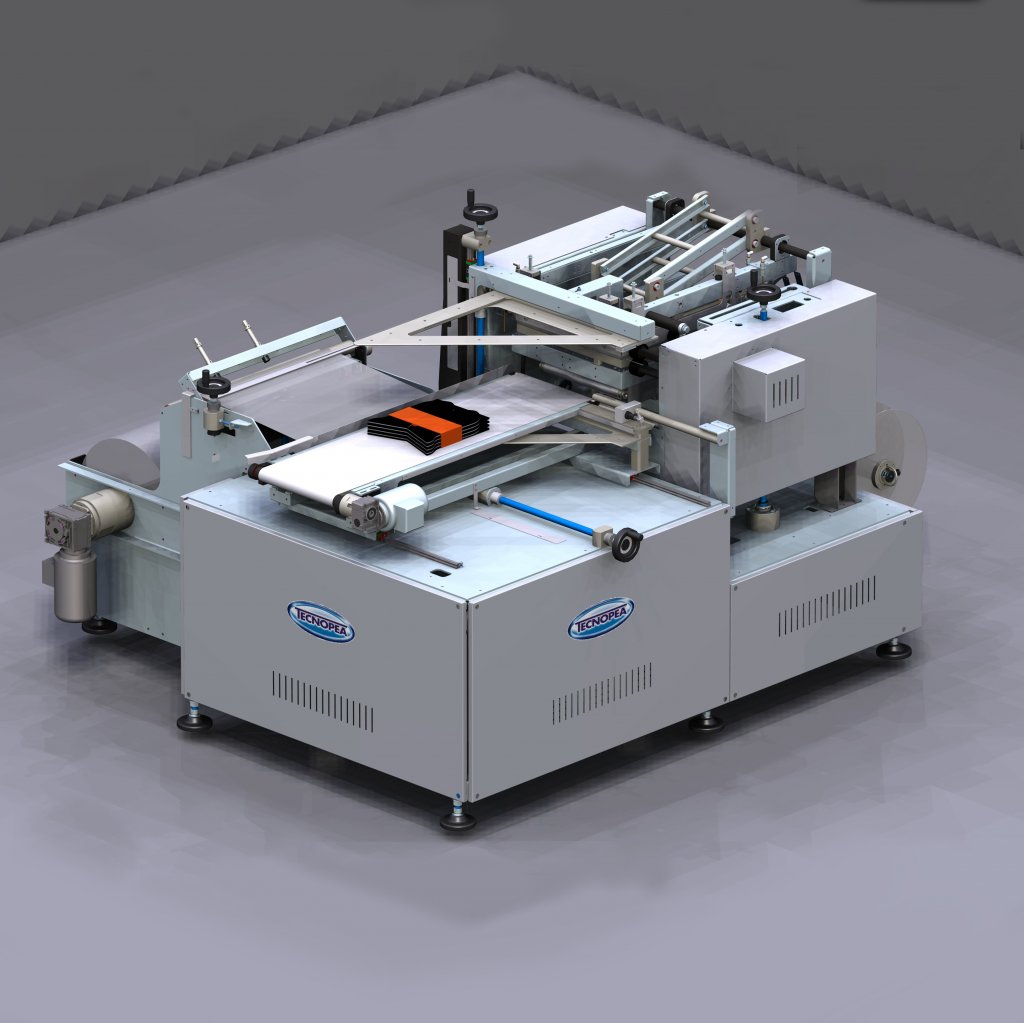

The system consists of two parts that can also be supplied individually.

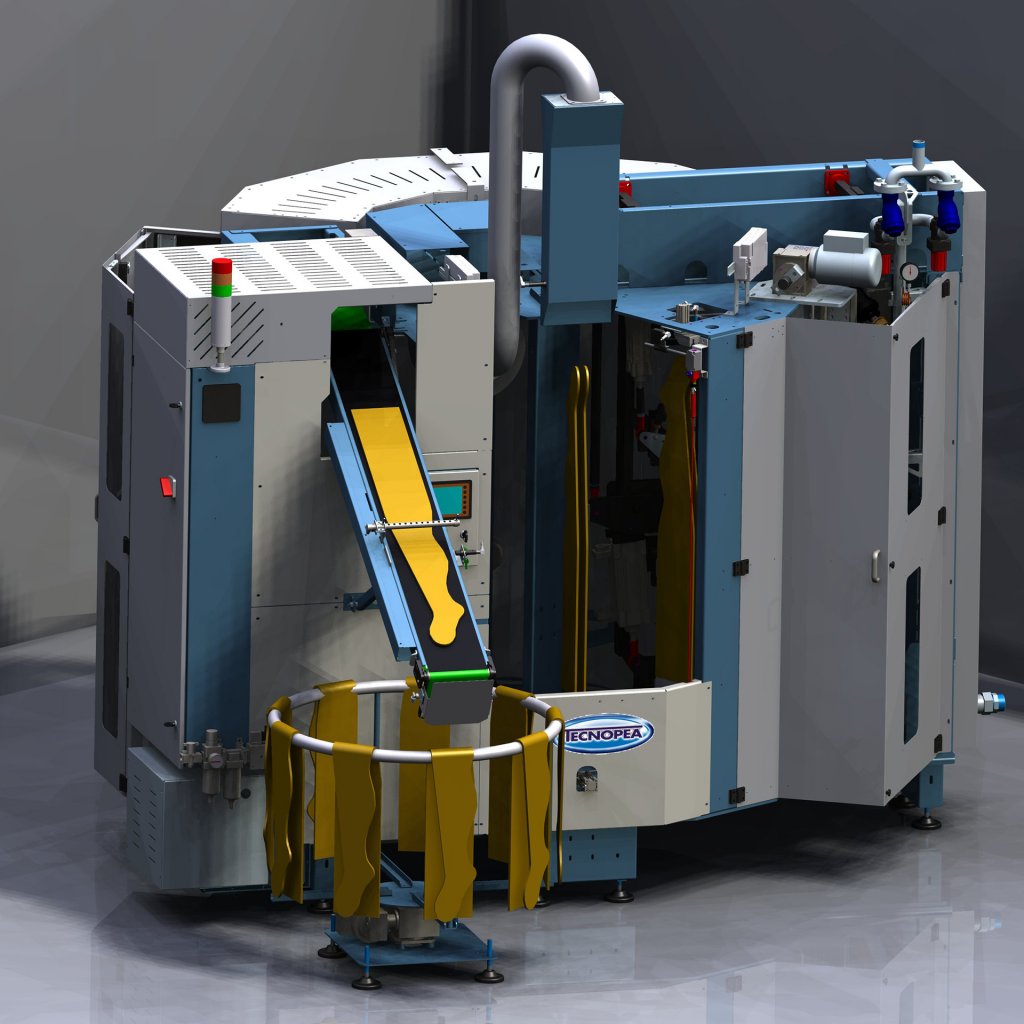

Loader + Boarding Machine

Steam boarding machine with 28 forms, steam chamber operating at a maximum pressure of 3 bar, equipped with an automatic device for positioning the elastics. The machine is fed by a high-speed automatic loader which provides for the correct orientation of the socks, by means of digital video cameras, and for their correct loading on the boarding forms. The extreme simplicity of the system means that only one operator can feed it while maintaining the maximum operating speed.

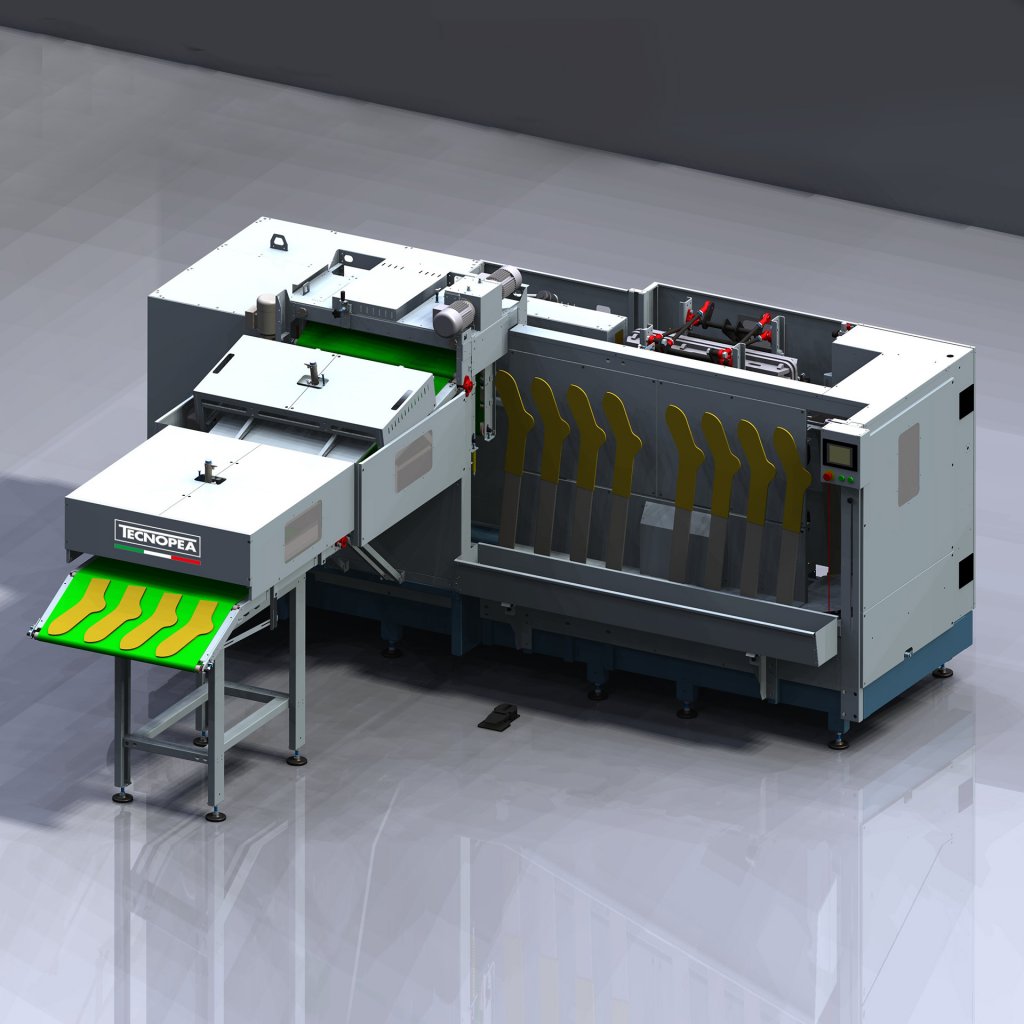

Socks assortment + Packaging

Automatic line for pairing and preparing socks for packaging with the selection of multiple folding and stacking options. The machine is connected directly to the boarding unit from which it receives the pair of socks, measuring their length and possibly discarding those outside the set tolerance. Through the graphic display all the options relating to the rotation, flipping and stacking of each pair can be easily selected in order to make the system very flexible and to use it for any presentation of the products required. Thanks to a very fast working cycle and its great flexibility, Soxmatic is able to feed various types of packaging machines obtaining products with cardboard rider, band and/or bag.

Data sheet

DIMENSIONS

9.583 X 4.250 x 2.290 (h)

WEIGHT

AIR CONSUMPTION

46,5 M3/h

INTERVALLO CONSUMO

INSTALLED POWER

14 kW

AIR PRESSURE

6 bar

MIN. CYCLE TIME

MAX PRODUCTION

BOARDING AND PACKAGING MACHINES FOR THE HOSIERY INDUSTRY

Would you like to be updated on Tecnopea news?